| Search products by INDUSTRY: | |

| (All Industries) | |

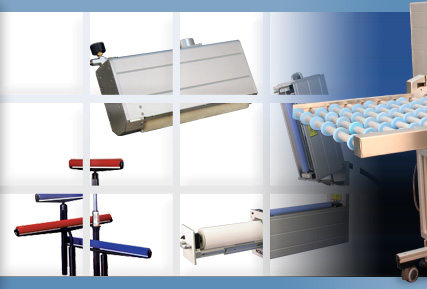

| Contact Panel Cleaning Machines | ||||||||

|

EC2 EconoClean is a perfect choice for pre-screen printing cleaning and many other similar processes. It can be used on polyester, PVC, polycarbonate, styrene, foam board, acrylic, and many others. Features: • 4 polymer roller • Operational modes include forward, reverse, forward/reverse • No need for shop air • Multiple tack levels for polymer rollers Options include: • Stand • Active anti-static system • Silicone-free cleaning system View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

HD2 Specially formulated polymer rollers lift and transfer contaminates from your product surface to adhesive rolls. It can be used for any process where a clean substrate is crucial. It can be used on cleaning panels or caul plates as heavy as 300 lbs. (150 kg) and is capable of cleaning extra wide rigid panels from 10 mil (250 microns) to 1 in. (25mm) thick. Features: • 4 polymer roller, 6 in. adhesive rolls with side access, anti-static • Operational modes include forward, and reverse • Pneumatic controls for adhesive roll engagement • Multiple tack levels for polymer rollers Options include: • Stand • Idle roller assembly • Silicone-free cleaning system View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

HDF6 The HDF6 is a large format panel cleaner that utilizes the same potent cleaning system as the rest of the MicroKlean line. This machine is fully programmable and can be supplied with drive conveyors. Much of the functionality of the IL4 is available in the HDF6. This machine is available is custom sizes. View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

IL4 IL4 utilize our cartridge system for fast and easy maintenance of the polymer cleaning rollers. As a result, maintenance of the tacky polymer cleaning rolls can be performed without removing the machine from the process line. This unique feature provides our customers with minimal down time for scheduled maintenance. In addition, the IL4 incorporates a Programmable Logic Controller (PLC) which enables custom programming, very precise control adjustments, and interfacing capabilities with other machines. Also available in a "Basic module" with only speed control and directional switch. Features: • 4 roller cartridge system, anti-static • PLC controls with high level of adjustability • Side access adhesive rolls • Pneumatic controls for adhesive roll engagement • Multiple tack levels for polymer rollers Options include: • Thin Film module • 8 in., 20 in., and 26 in. disc conveyors • 20 in. band conveyors, tables (for thin material) View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

IL4 - Thin Film Module Specially formulated polymer rollers lift and remove contaminates as small as 1 micron in size, from your product surface. No special chemicals, wipes, or handling needed. Also available with conveyors Features: • 4 segmented polymer rollers, 3 in. adhesive rolls, anti-static, stand • Operational modes include forward, reverse, and forward/reverse • Pneumatic controls for adhesive roll engagement • Multiple tack levels for polymer rollers Options include: • Side pullout thin film cartridge and adhesive rolls • Conveyors (not recommended for very thin or non-rigid material) View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

QD2 The QD2 offers increased cleaning efficiency of the IL4 by doubling the number of polymer cleaning rollers and adhesive rollers. QD2 utilize our cartridge system for fast and easy maintenance of the polymer cleaning rollers. As a result, maintenance of the tacky polymer cleaning rolls can be performed without removing the machine from the process line. This unique feature provides our customers with minimal down time for scheduled maintenance. In addition, the QD2 incorporates a Programmable Logic Controller (PLC) which enables custom programming, very precise control adjustments, and interfacing capabilities with other machines. Also available in a "Basic module" with only speed control and directional switch. Features: • 4 roller cartridge system, anti-static • PLC controls with high level of adjustability • Side access adhesive rolls • Pneumatic controls for adhesive roll engagement • Multiple tack levels for polymer rollers Options include: • 8 in., 20 in., and 26 in. disc conveyors • 20 in. band conveyors, |

|||||||

|

||||||||

| Back to Top |

||||||||

|

SMTC-2 The SMTC-2 is a contact cleaning machine for the circuit assembly industry. The machine features a clamshell opening for easy maintenance. To allow for the cleaning of small boards, the SMTC-2 has an internal conveying system that guides the board through the machine and assists it to the exit side. The conveying system is supported by a high precision linear slide, allowing for very fine adjustments in board widths. Standard size is up to 16-inches wide. Available in 2 and 4 cleaner roller format. View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

TC Tabletop Cleaner The TC cleaner offers the same high efficiency cleaning found in all the other SDI tacky roller cleaners. With a cleaning width of 12" (305mm), the TC is an economical answer for small parts cleaning. Despite it's affordable price, the TC is designed for industrial applications and is constructed of aluminum. The TC features SafeStart which places all of the machine functions into one single lever. Antistatic and a tiltable stand are available as options View product data sheet. |

|||||||

|

||||||||

| Back to Top |

||||||||

|

WC6D (Driven) WC6D is a perfect choice for cleaning wide format substrates just prior to screen printing and many other similar processes. It can be used on polyester, PVC, glass, polycarbonate, styrene, foam board, acrylic, and many others. Features: • Economic panel cleaner for larger size panels. • Controls include speed control and direction selector • Front access for 6 in. adhesive paper rolls • 2 polymer roller and anti-static included • Pneumatic controls for adhesive roll engagement • Multiple tack levels for polymer rollers Options include: • Silicone-free cleaning system • Higher powered AC anti-static • Idler roller assembly |

|||||||

|

||||||||

| Back to Top |

||||||||

HOME | ABOUT US | INDUSTRIES | PRODUCTS | REFURBISHED PRODUCTS | FAQS | CONTACT US

© SDI SYSTEMS DIVISION, INC. ALL RIGHTS RESERVED